VIP consists of barrier bag, getter and vacuum insulation core material.

The role of getter is to absorb the possible existence of oxygen, nitrogen and water, etc., to maintain the dryness of the core material, avoid expansion and shorten the service life. There are three kinds of getter: desiccant, catalytic getter, barium lithium getter.

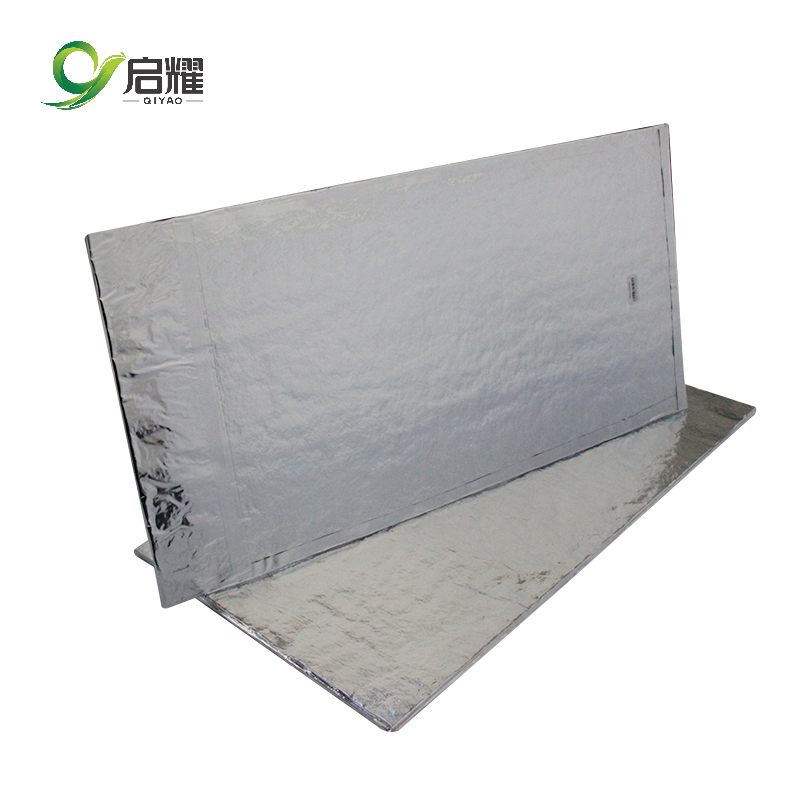

There are two kinds of barrier bags, glass fiber cloth and aluminum foil bags.

Core material: glass fiber insulation felt and high silicon oxygen fiber insulation felt. Conventional fiberglass, high-silica fibers work better, but cost more.

VIP board application

1. Construction: External wall insulation, generally have the industry standard size. The general size is 600*400mm, 200*400 and 200*600mm for the master cutting formation. The conventional thickness is 5/10/15/20/25/30mm.

2. Home appliances: refrigerator, air conditioning insulation layer.

3. Refrigerator, cold chain insulation board.